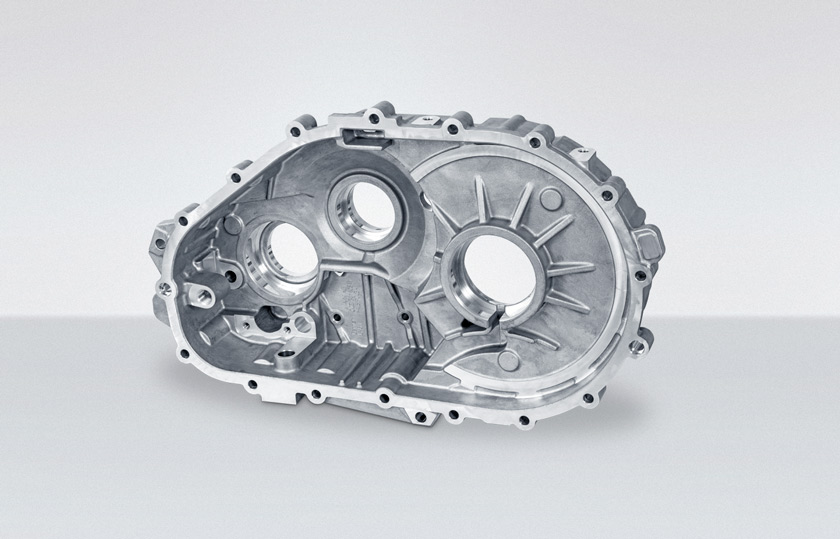

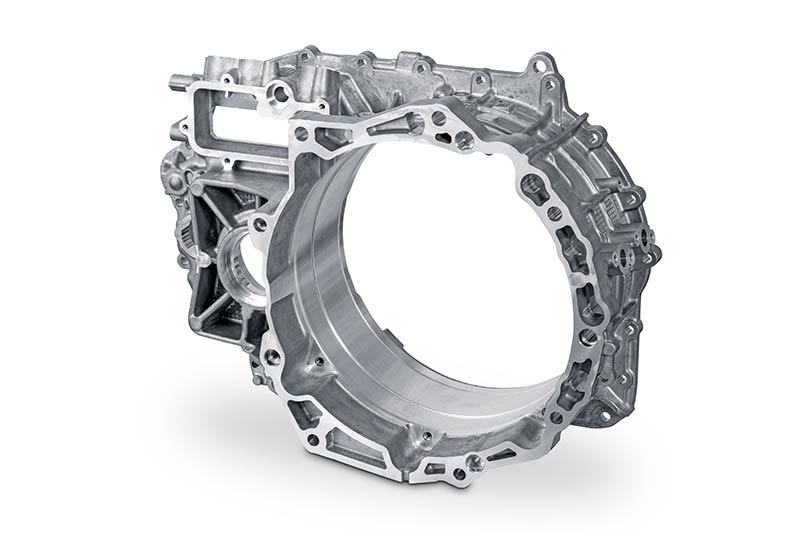

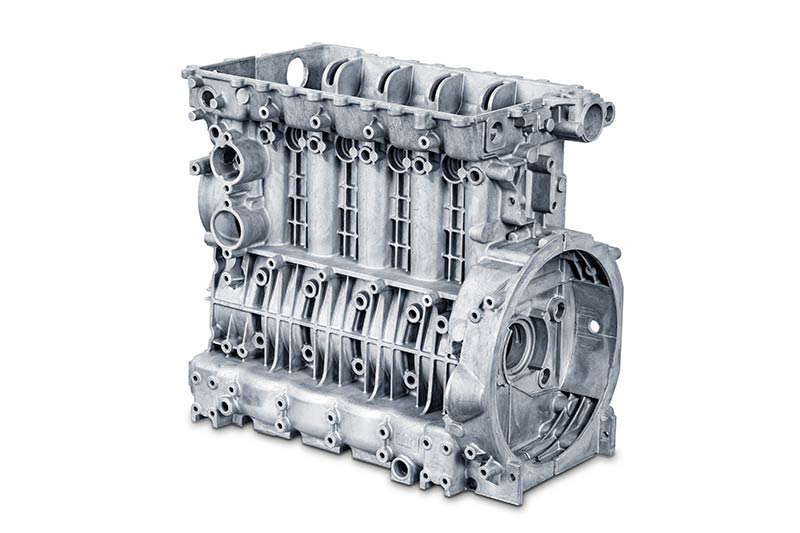

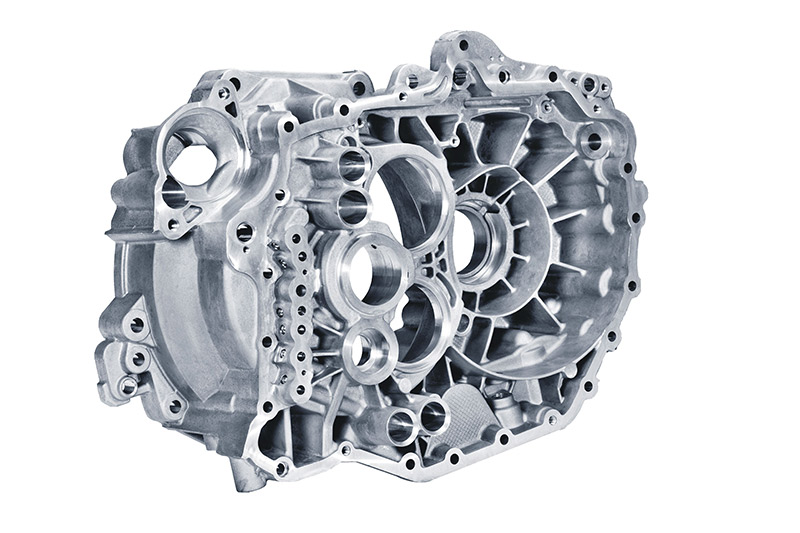

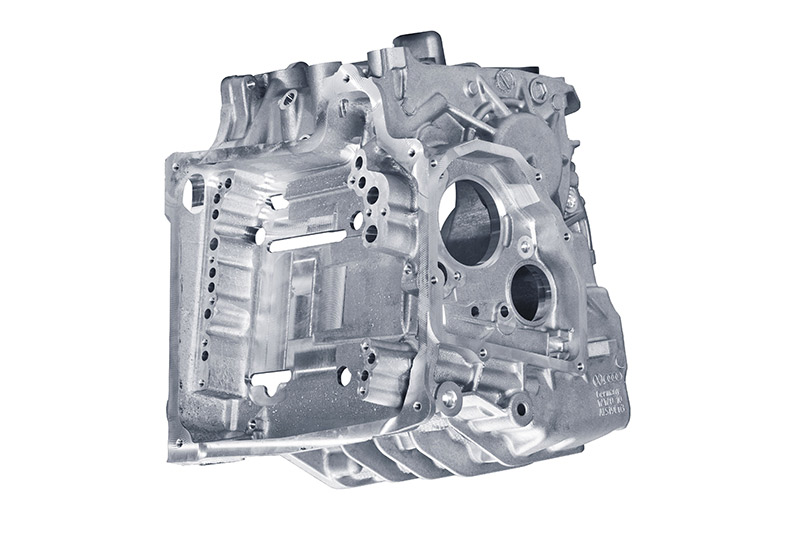

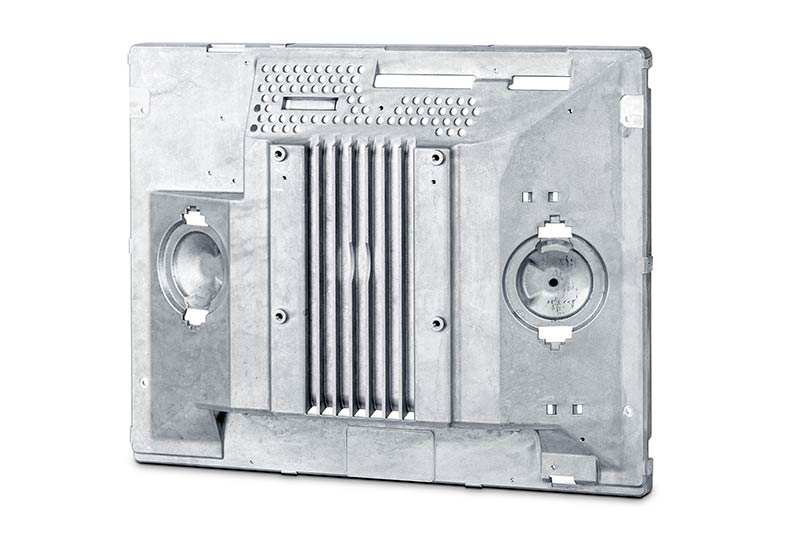

Die castings made of aluminium

Due to its low weight and high specific strength, aluminium is excellently suited for lightweight construction, for the automotive, aviation and aerospace industries. The mechanical properties of aluminium such as tensile strength, hardness and thermal conductivity surpass those of the lighter magnesium. Aluminium is extremely corrosion resistant. This self-protection can be further enhanced by methods such as coating. Another advantage of aluminium is its electrical conductivity and magnetic neutrality, which is why it is often used for the construction of electronic components.

Contact us